Treatment Equipment

The facility is designed for safe and efficient firefighting training. It includes smoke processing equipment and foam fire extinguishing wastewater treatment equipment, suitable for mid-rise training buildings, to handle the black smoke from oil fires and wastewater from foam fire extinguishing materials. It is designed to enable firefighters to conduct firefighting training safely and efficiently.

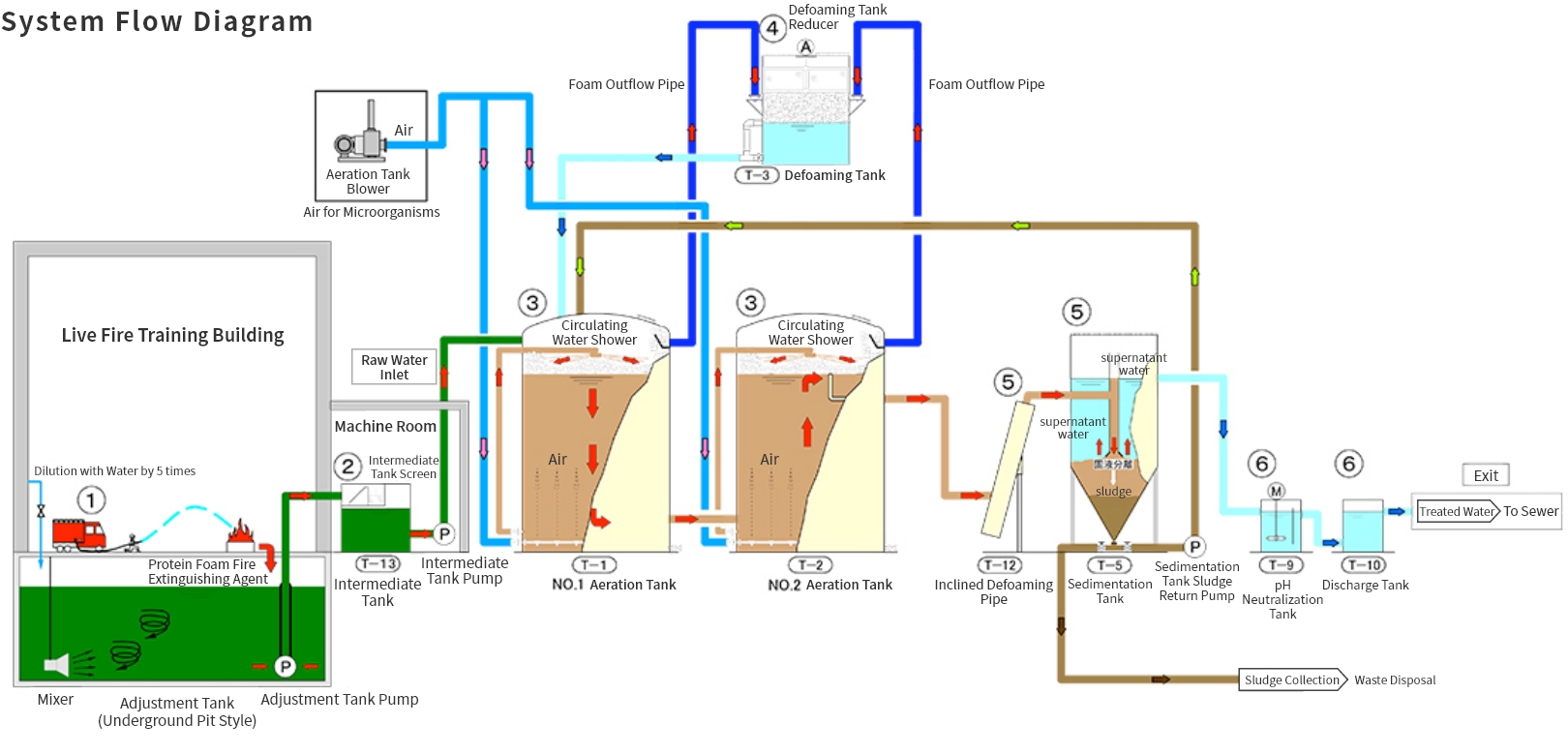

Foam Fire Extinguishing Wastewater Treatment Equipment

-

Underground Pit

- The protein foam fire extinguishing agent used for firefighting training is diluted to 3% and discharged.

- The foam that lands on the floor is washed with tap water, diluted about five times, and flows into the underground pit.

- In the pit, it is uniformly stirred using a mixer and an adjustment tank pump.

-

Intermediate Tank

- The protein foam fire extinguishing agent stored in the underground pit is led to the intermediate tank screen, where large debris is removed.

- After removing large debris, the agent is introduced from the intermediate tank pump to the aeration tank.

-

Aeration Tank

- The protein foam fire extinguishing agent moved to Aeration Tank No. 1 begins to decompose by microorganisms.

The process is further enhanced by passing through Aeration Tank No. 2.

- The protein foam fire extinguishing agent moved to Aeration Tank No. 1 begins to decompose by microorganisms.

-

Defoaming Tank

- The bubbles generated in the aeration tank are led to the defoaming tank, where they are eliminated before being returned to the aeration tank.

The process is further enhanced by passing through Aeration Tank No. 2.

- The bubbles generated in the aeration tank are led to the defoaming tank, where they are eliminated before being returned to the aeration tank.

-

Inclined Defoaming Pipe, Sedimentation Tank

- The treated water decomposed by microorganisms in the aeration tank, along with some sludge, is led to the inclined defoaming pipe to separate into treated water and bubbles.

- Then, it is introduced into the sedimentation tank, where it separates into supernatant and settled sludge.

- The settled sludge is returned to the aeration tank.

The sludge is checked during regular inspections, and excess sludge is extracted and treated as industrial waste.

-

pH Neutralization Tank, Discharge Tank

- The separated supernatant is neutralized in the pH neutralization tank with caustic soda, then discharged into the sewer system via the discharge tank.

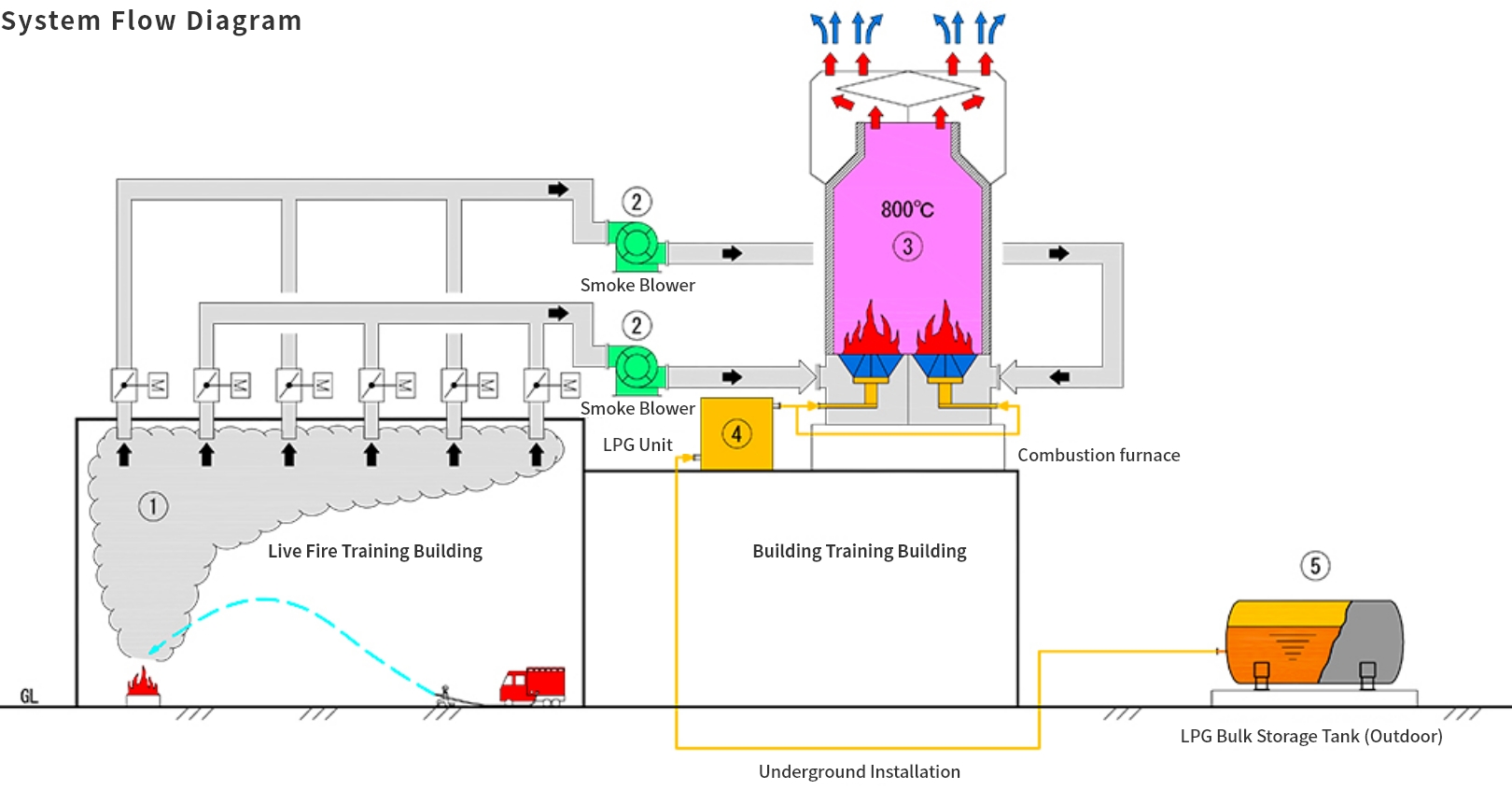

Smoke Processing Equipment

-

Live Fire Training Building

- Kerosene is burned in an oil pan, and firefighting training is conducted using protein foam fire extinguishing agents.

-

Smoke Blower

- The combustion gases generated are drawn in through the training building's ceiling intake using ducts and a smoke blower, then directed to the combustion furnace.

-

Combustion Furnace

- The combustion gases are re-burned inside the combustion furnace at 800°C to clean them before being released into the atmosphere.

-

LPG Unit

- Controls the flow rate of LPG gas necessary to maintain the internal temperature of the combustion furnace at 800°C.

- As a safety device, an emergency shutoff valve (activated at a seismic intensity of 5 or higher) is installed internally.

-

LPG Bulk Storage Tank

- LPG is stored as fuel for the combustion furnace.