ALL in "ONE" ~Everything related to the plant~

Get in touch with any concerns you have regarding plants!

We are here to assist you in all situations, both domestic and international.

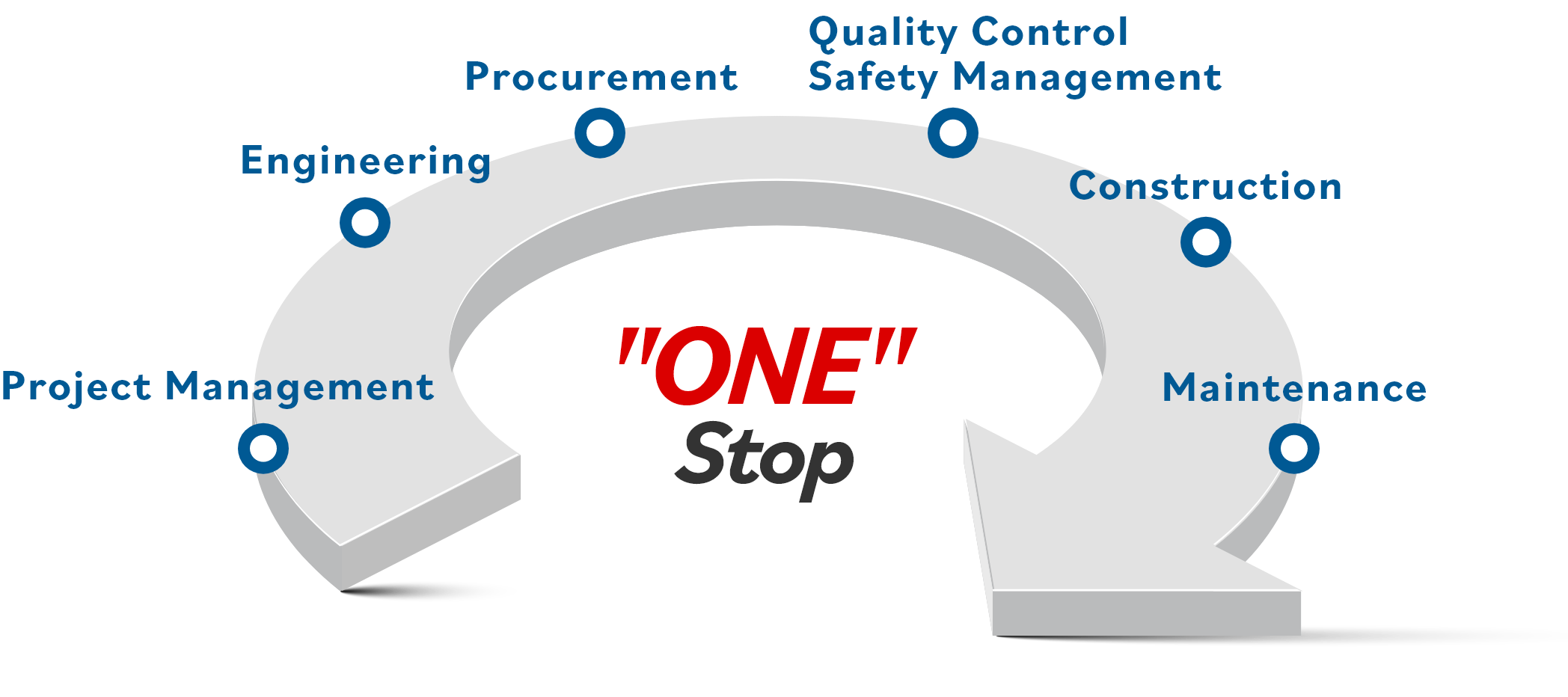

Basic planning, FEED, Feasibility Study, various analyses, EPC, modifications, plant maintenance, regular overhauls, equipment procurement, etc.

CONTACT

We are here to assist in every situation.

Please consult us with any concerns you have about plants!

Basic planning, FEED, Feasibility Study, various analyses, EPC, minor modifications, plant maintenance, regular overhauls, equipment procurement, etc.

"ONE" Team The Strengths of JFE Project One

We work together with our customers.

-

We support you in plant construction right from the research and development level.

-

We have experience with various types of fluids (powder, slurry, ultra-high pressure fluids (up to 300MPa), high-viscosity fluids, etc.)

-

We assist in creating PDPs, supporting basic design, and preparing ITB (Invitation to Bid) documents, among other things.

-

We have extensive experience in Southeast Asia, especially in Singapore and Thailand, and we support our customers in their overseas expansion.

| Examples of Design Collaboration from the Basic Design Stage | ||

|---|---|---|

| Facility | Outline | Detail |

| Polymer Plant | Considering equipment during manpower shortages or with tight delivery schedules | Examining equipment sizing to equipment placement considerations, creating equipment and instrumentation lists, etc. We support the creation of client ITBs (Invitation to Bid) and related tasks. |

| Basic Chemical Plant | Examining constructability and cost-effectiveness under challenging site conditions | Including layout planning, heavy machinery planning, and transport planning, we develop and propose feasible plans. |

| Distillation Equipment | Examination of the need for modification and capacity verification of existing equipment due to changes in operating conditions | From conducting process simulation to proposing layout planning and on-site construction methods |

| Intermediate Materials for Electronic Components | Batch Reactor Tanks & Fixed Catalyst Continuous Reactor Tanks, Filtration and Recovery of Powdered Catalysts, Distillation Equipment for Reaction Liquids | Developing basic designs based on the demonstration data from the customer's laboratory |

| Solvent Recovery | Incorporating a heat pump system into the distillation tower for energy saving measures | Proposal of basic design based on our own technology |

"ONE" of a kind

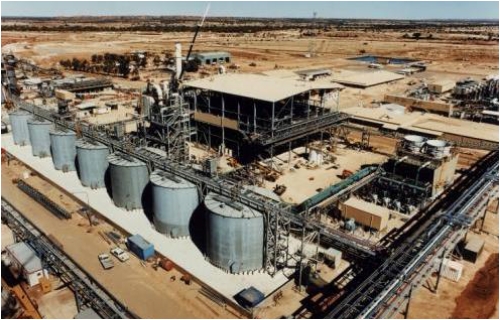

Petrochemicals

Accumulated expertise in the petrochemical field through numerous achievements.

Beginning with the construction of Japan's first ethylene plant, we have numerous achievements both domestically and internationally.

(Including the projects executed under the name of Mitsui E&S [formerly Mitsui Engineering & Shipbuilding Co., Ltd. ('MES')], we have over 1,000 achievements in more than 40 countries worldwide.)

For various monomer/polymer plants,

we provide extensive support including Feasibility Study, FEED, EPC (Engineering, Procurement, and Construction), plant maintenance, and modifications to existing facilities.

Oil Refining

We have a track record of delivering numerous to refineries both domestically and internationally.

- Our expertise includes a wealth of knowledge in process and distillation system engineering, incorporating our proprietary tray technology.

- We also pride ourselves on being one of the leading domestic achievers in crude oil desalting and in the areas of alkylation and spent sulfuric acid recovery.

We also have numerous achievements in modifications of existing facilities to comply with various regulations.

- This includes accomplishments in reinforcement construction for disaster response.

- We demonstrate our strength in existing facility modifications, from basic planning to the EPC (Engineering, Procurement, and Construction) stage, in response to environmental regulations such as IMO regulations, as well as in energy-saving evaluations and modifications.

Inorganic Chemistry

We have a wealth of experience in sulfuric acid plants

- Through a technical partnership with the former Monsanto Company, we have constructed 69 plant installations both domestically and internationally.

- We also carry out numerous renovations of outdated equipment.

- We provide SX material and ZeCo material, which are excellent in corrosion resistance.

We also have numerous accomplishments in various inorganic chemical plants

- We have a wide range of experience in inorganic fields, including hydrochloric acid recovery, phosphoric acid, nitric acid, and fertilizer manufacturing plants.

- We are continually challenging new initiatives such as the automation of salt production facilities, leveraging our expertise, and making proposals tailored to our customers' needs.

Others

We are one of the few domestic engineering companies that possess a specialized unit for heating furnaces

- We have numerous achievements in various facilities such as heating furnaces, cracking furnaces, hydrogen reformers, and flares.

- We broadly handle everything from fuel conversion of existing furnaces (including those made by other companies) to energy-saving evaluations.

We conduct feasibility studies for the introduction of HTS (inorganic molten salt-based heat transfer medium).

It can be used at high temperatures (operating temperature range: 300-550°C).

We have extensive experience with facilities subject to the High Pressure Gas Safety Act

- Capable of handling self-certified construction of piping.

- Seismic strength calculations using SEISMIT-TW, SP, etc. (Level 1, 2).

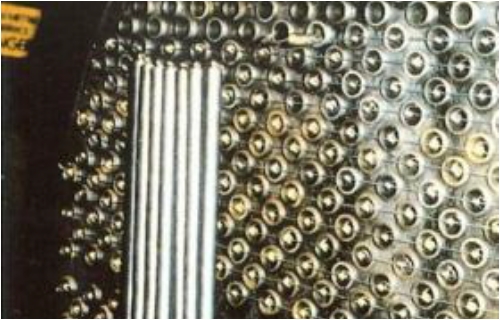

Spirelf (Dirt Preventer)

- Prevents dirt inside the tubes of multi-tube heat exchangers (contact + turbulent effect).

- Developed by the former ELF company in France.

- A spring-like metal device is installed inside the tube and fixed at both ends of the tube for use.

Dense Smoke and Hot Air Live Fire Training Device

- A hot training facility where firefighters experience dense smoke and hot air.

- We have also developed a VR system for a safer experience.